This is where the DELMIA Equipment Allocation application is used. Having previously created a Process Plan your Industrial Engineers are able to create a Resource structure, which defines the resource scope on which the Process Plan can be executed, to balance the production line of operations with the available resource (shopfloor workers, machine tools, hand tools). It allows Process Engineers to author manufacturing systems, manage system structures, balance manufactured items between systems and balance operations between systems.Īgain, scoped links are used to link the Process Plan to the MBOM to ensure that the Process Plan and MBOM remain in-sync with each other. Having created an MBOM the next step is to create a Process Plan, this is where the DELMIA Process Planning application is used. These links ensure the EBOM and MBOM remain in-sync with each other. The MBOM is linked to the EBOM through scope links. This is where DELMIA Manufacturing Item Definition application is used to consume the EBOM and create an MBOM (a Manufacturing Bill of Material) that meets the requirement of Process and Industrial Engineers. When Manufacturing – those responsible for ensuring that the product can be manufactured – receive the EBOM, they may find that they are unable to consume the EBOM in its current form.

It’s often structured in a way that suits Engineering and not necessarily suitable for manufacturing.

Your Engineering Designers create an EBOM (Engineering Bill of Material) with your CAD tool, e.g.

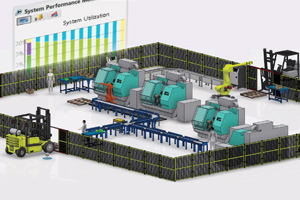

It incorporates Product Data Management (PDM) and Product Lifecycle Management (PLM) through ENOVIA with the additional integration of Dassault Systèmes’ other brands such as SIMULIA for Simulation, CATIA for Computer-Aided Design, and more. It provides digital continuity to empower every organization in your company – from marketing to sales to engineering.ĭELMIA 3DEXPERIENCE enables manufacturers to create digital models that virtually simulate products, processes, and factory operations. The 3DEXPERIENCE platform is a collaborative platform. Imagine building the factory and products virtually, being able to simulate and optimize new manufacturing system designs, as well as validate production schedules before even setting foot into the actual production facility. What if all the flaws and potential waste that only become evident during or after manufacturing could be identified at the earliest stages of the process? This is where Virtual Twin technology comes in to play.ĭeveloping and building an accurate digital version of a factory, a product and the operational assets that create the product can have a huge positive impact on the success of manufacturing processes, effectiveness and viability. What is Digital Manufacturing?ĭigital Manufacturing drives manufacturing innovation and efficiency by planning, simulating, and modeling production processes in the virtual world. It’s often referred to as the manufacturing arm of the 3DEXPERIENCE platform.ĭELMIA provides solutions to leverage the virtual world of modeling and simulation with the real world of operations to provide a complete solution to value network stakeholders: From suppliers, to manufacturers, to logistics and transportation providers, to service operators and work forces.ĭELMIA is an acronym for Digital Enterprise Lean Manufacturing Interactive Application. DELMIA is an integral part of the Dassault Systèmes 3DEXPERIENCE platform, it is the connection between the virtual and real worlds.

0 kommentar(er)

0 kommentar(er)